Contact us

Call us at

Available 6:00 AM – 5:00 PM (PST) Business Days

Download

Download Manuals, Datasheets, Software and more:

Feedback

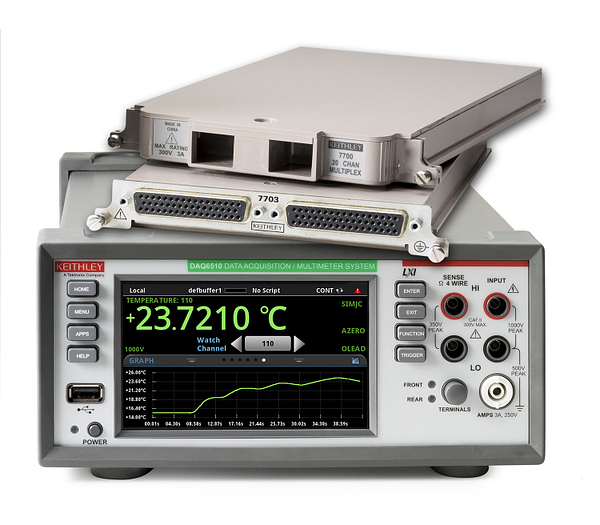

Keithley Switching and Data Acquisition (DAQ) Systems

What is a DAQ System?

A DAQ (Data Acquisition) system is a comprehensive setup for measuring and collecting data from various sensors or transducers, crucial in fields like scientific research, industrial automation, and more. It typically includes:

- Sensors or Transducers: Converting physical or electrical signals into measurable quantities.

- Signal Conditioning Circuits: Amplifying, filtering, or digitizing signals for enhanced quality and accuracy.

- Data Acquisition Device: Sampling and digitizing signals for further analysis.

Enhanced Your Data Measurement with Keithley's DAQ Systems

As a leader in test and measurement technology, Keithley provides DAQ systems that are not just high-performing but highly adaptable, meeting the needs of diverse industries from environmental monitoring to automotive testing.

Why Choose Keithley DAQ Systems?

Keithley’s DAQ systems are renowned for their high accuracy, high-speed scanning, flexible configuration, user-friendly software, and industry-leading support. They offer a unique blend of precision, efficiency, and innovation, making them ideal for a wide range of applications in various industries.

DAQ System Enhanced Monitoring and Testing Applications

Keithley's DAQ systems are specifically designed to address a wide range of monitoring and testing applications. These systems provide accurate and reliable data, essential for industries requiring detailed analysis and quality control. From environmental monitoring to product testing, Keithley’s advanced technology ensures superior performance in various critical applications.

- Environmental Monitoring: For precise monitoring of environmental conditions.

- Burn-in and Accelerated Life Testing: Identifying potential weaknesses in products, enhancing durability and performance.

- Failure Analysis: Investigating root causes of product failures to improve design and performance.

Specialized Automotive and RF Testing Solutions

Keithley's DAQ systems excel in automotive testing, equipped to handle various components:

- Airbag and Seat Belt Testing: Systems designed for testing airbag inflators and seat belt pre-tensioners, ensuring safety.

- Wiring Harness Analysis: Efficient testing solutions for automotive wiring harnesses.

In RF and microwave device testing, Keithley offers:

- High-Frequency Testing: A microwave switch system with up to 40 GHz bandwidth, suitable for intricate device testing.

Advanced Features for Diverse Testing Needs

Keithley's DAQ systems are tailored for complex testing scenarios:

- Extensive Channel Support: Up to 576 channels for large-scale data acquisition.

- Precision Measurements: High-precision data capture using 61⁄2-digit and 71⁄2-digit DMMs.

- Compliance with Standards: Aligning with MIL-STD-1553 for broad industry applicability.

- Versatile Applications: Ideal for aerospace, defense, and more, thanks to adaptable features.

Key Considerations in Choosing a DAQ System

When selecting a DAQ system, consider:

- Accuracy and Resolution: Essential for precise measurements.

- Sampling Rate: Important for applications with rapidly changing signals.

- Signal Conditioning: Amplifying and filtering for various sensor types.

- Software Compatibility: User-friendly software with data visualization tools.

- Channel Count: For handling multiple signal types.

- Environmental Adaptability: Operating under specific conditions.

- Budget Constraints: Balancing cost with functionality.

Leveraging Advanced Techniques in DAQ Systems

Keithley integrates advanced calibration, isolation in measurement accuracy, and high-speed signal streaming with remote monitoring capabilities. These advanced techniques ensure reliable, accurate measurements and operational flexibility.

Conclusion

Keithley's DAQ systems are comprehensive solutions designed to meet the evolving needs of data acquisition and analysis across various sectors. Embracing a Keithley DAQ system means committing to the highest standards of precision, efficiency, and technological advancement in your testing and measurement processes.

FAQs: Data Acquisition (DAQ) Systems

What is DAQ, and why is it important?

Data Acquisition (DAQ) is a process of gathering and analyzing data from various physical phenomena. It plays a crucial role in engineering, scientific research, and industrial settings, enabling real-time monitoring and control of parameters like temperature, pressure, and voltage. DAQ is essential for quality control, process optimization, and troubleshooting.

What is the purpose of data acquisition?

What does a DAQ system measure?

A DAQ system can measure a wide range of physical or electrical phenomena, including:

- Temperature: Using thermocouples, RTDs (Resistance Temperature Detectors), and thermistors.

- Voltage: Measuring across components or power sources to monitor electrical systems.

- Current: Often measured with shunts or transformers to understand power flows.

- Pressure: Using pressure transducers or sensors to monitor fluid or gas pressure in pipelines or systems.

- Force and strain: Through strain gauges or load cells to assess structural integrity or mechanical performance.

- Sound: Captured via microphones to analyze noise levels or sound frequencies.

- Light intensity: Measured with photodiodes or light sensors for various applications, including environmental monitoring.

What are the types of data acquisition?

Data acquisition systems can be classified based on their functionality and the method of data collection:

- PC-based DAQ: Utilizes the processing power, display, and connectivity of personal computers with DAQ hardware for data collection and analysis.

- Standalone or portable DAQ: Independent systems that can operate without a PC, often used for field measurements or when portability is required.

- Networked DAQ: Systems connected over a network, allowing for remote monitoring and control across multiple locations.

- Modular DAQ: Systems that can be customized with different modules for various types of inputs and outputs to meet specific application requirements.

What is the DAQ process?

The DAQ process typically involves several key steps:

- Signal Conditioning: Modifying the raw signal from the sensor to make it suitable for digitization. This may include amplification, filtering, and isolation to ensure accurate measurements.

- Sampling: The act of measuring the signal at discrete intervals to convert the continuous analog signal into a series of digital values. The rate of sampling is crucial for accurately representing the signal.

- Analog-to-Digital Conversion (ADC): The conditioned analog signal is converted into a digital format by the ADC. The resolution of the ADC affects the precision of the measurement.

- Data Storage and Analysis: The digital data is then stored and analyzed using specialized software to understand the measured phenomena and make informed decisions.

- Feedback/Control: In many applications, the analyzed data can be used to make adjustments or control a process, creating a closed-loop system for automation and optimization.